|

CPS - Contactless Power System |

CPS for conveyors

In March of 1999 the CPS technology was introduced for conveyor applications. Since then

a number of systems have been installed on assembly conveyor lines in several automobile factories. These conveyor

lines, which include track switches and lift stations, are up to 285 meters long with as many as 46 trolleys powered from

a 45 kW primary power supply. Additional trolleys are easily accommodated.

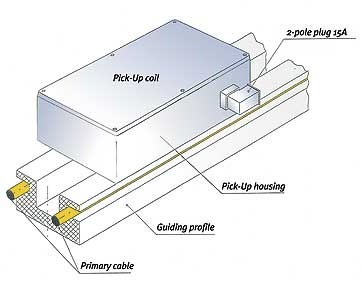

For floor-mounted installations the primary power cable is carried in underfloor plastic supports which includes a

slot for the trolley guide rollers. This slot is not required for power transmission but provides a convenient and cost-saving

method of conveyor guiding.

The following features highlight the capabilities of CPS for conveyor applications:

- Full functionality in all track areas, including curves, switches and lift stations.

- Primary cable installation under any metal-free floor.

- Flexible, small-diameter primary cables which easily accommodate tight track curves.

- Compact, space-saving pickup units magnetically coupled to the primary cable and mounted on the

conveyor trolleys.

- Pickup units designed for output voltages ranging from 24 to 560 VDC, with power ratings of 300 to

3000 watts, per customer requirements.

-

In the future integrated data transmission as well as integrated inductive tracking guidance will complete this

concept. Peripheral components which are now required along the track, such as photoelectric sensors, RF transmission

or other control equipment, will then no longer needed.

|

|

|

EMV and EMF tested

All CPS components have been tested and certified by independent laboratories and comply with all

regulations pertaining to electrical interference and noise immunity as well as the allowable magnetic field

strength for personnel safety.

Emergency-Stop

Where an emergency-stop function is required it can easily be implemented utilizing the advanced electronics of

the CPS primary power supply. In an emergency situation the CPS system can be immediately shut down in its entirely.

Large Motion Tolerance

The optimum distance between the pickup unit and the surface of the primary cable is 15 mm. The horizontal tolerance is +/- 25 mm, allowing generous freedom of trolley movement. This guarantees a stable

power supply under all operating conditions.

Power Sectioning

In applications where power sectioning and separation is necessary, selected sections are fed by under-floor cables

carried in cable trays.

|

|

|