High-tech manufacture

More and more automobile manufactures are using floor transport systems with CPS

The range of applications of the "Contactless Power System" (CPS)

from VAHLE grows constantly. After a CPS pilot system was installed on a container crane in the USA

in the summer of 1997, the automobile industry has been using this technology of the future

from Kamen.

In the autumn of 1998, one of the European automobile manufacturers started to use

the CPS technology from VAHLE. For the first time a production line was equipped with

a floor transport system using a contactless power supply. The traditional conductor

systems which had been used before functioned reliably; however, they required

frequent maintenance. Therefore, it was time for CPS. It is used for the assembly

of the car chassis and the gearbox/engine unit. Because of the system's completely

contactless mode of operation, maintenance is reduced to a minimum. This is a

decisive factor, since this can considerably increase the availability and lifetime of the

transportation system.

37 vehicles simultaneously

The floor transport system for the assembly of the chassis consists of a 174 m

long line with three switches and two lifting stations. The chassis joins the car body

at the lifting stations. A total of 22 carriers are in use on this line. The

approx. 120 m long floor transportation system for the assembly of the gearbox/engine

units including one switch is equipped with a total of 37 carriers.

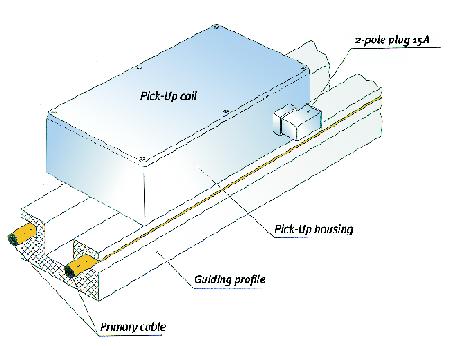

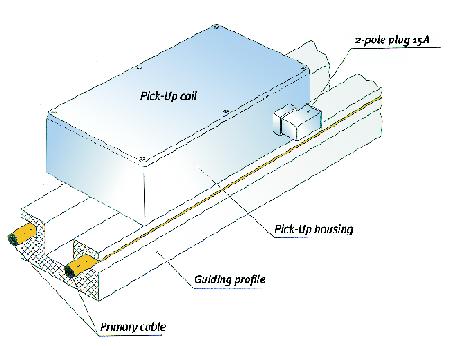

The CPS system transfers the power to the two assembly lines using the principle

of induction, similar to that of a conventional transformer in which the primary

and the secondary winding are on a closed ferromagnetic core, in the CPS system

the stationary primary winding is straightened to a long conductive loop. The mobile

secondary winding (pick-up coil) is placed on an open ferromagnetic core and coupled

with the magnetic field of the primary winding. This enables the two windings to move

freely relative to each other.

Optimum power transmission

An optimum and low-loss power transmission is provided by the CPS primary inverter which transforms the 50 Hz A.C.

main voltage into a single-phase 20 kHz voltage and then feeds it to the CPS

primary conductor. Each assembly line has a central 45 kVA feed terminal. The

primary inverter was generously dimensioned for the given number and the power range of

the carriers and it even allows for a further expansion of the line with extra carriers.

For optional reasons, the customers demanded that selected sections of the

installation where to be switched off. This requirement was met by technical

alterations of the CPS system. The primary cable is installed underfloor in a

guide profile specially designed for this application. The external groove in

the plastic profile is of no significance for the CPS system; only serves to guide

the carrier with a guiding roller mounted to its running gear.

What happens when the carriers come close to the switches and lifting stations?

Here the primary cable is interrupted and fed separately. The dead area between

the sections is reliably bridged by a special design of the pick-up elements.

The flat shape of the pick-ups allows a space-saving mounting under the carrier.

The ideal gap between the pick-up unit and the surface of the guide rail is 15 mm.

This distance allows large movement tolerances of the carrier and guarantees a

reliable power transmission under all operating conditions.

CPS - the right path

The great interest of the industry in this innovative technology shows that VAHLE was on the right

track when deciding to develop and market the CPS system. VAHLE is convinced that

the CPS technology, due to its advantages over conventional systems, will prevail

on the market soon

Oktober 1999